Each tool will take different machining parameters for different machining materials. In the field of milling, tool manufacturers aim to improve processing efficiency by optimizing tool material and developing more targeted coating technologies.(ALUMINUM ENCLOSURE CUSTOM)

Through the combination of various elements in the material, we can see thousands of raw materials that can be processed. To process these materials, we know the processability of the material, and we also know how to optimize the processing.

The material group to which the workpiece belongs

According to the ISO 531:1966 international standard, the machinable materials are divided into 6 major categories, which are:

The steel material represented by P;

Stainless steel material represented by M;

Cast iron material represented by K;

Non-metallic materials represented by N;

High temperature material represented by S;

High hardness material represented by H;

Within these broad categories, tool manufacturers group materials into smaller categories based on their tensile strength and hardness. If we can’t find the machining performance parameters of the material to be machined in these small categories, the feasible way is to consult the tool supplier, I believe they will be happy to help you solve this problem.(CNC machining)

Calculation formula

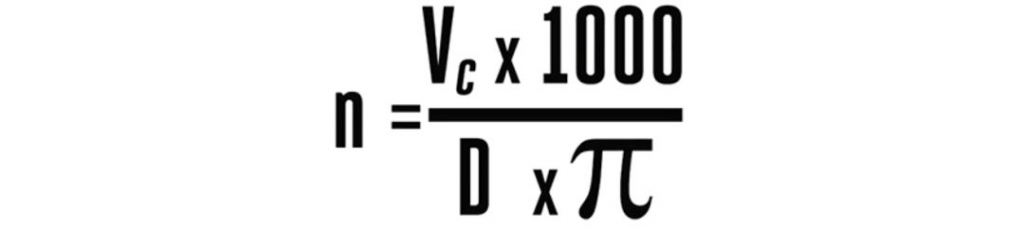

We usually see the formula below in tool manuals

Before talking about this formula, let’s recall that we have learned about the circumference formula of a circle:

C (perimeter) = π (pi) * d (diameter)

According to this formula, we can conclude that the distance traveled by a point on the periphery of the tool for each revolution of a tool with a diameter of D is:

pi*D

Then, when the tool rotates at a frequency of n revolutions/1 minute, the distance traveled is:

n*π *D

According to the formula of time (T)×speed (V)=distance (S ), the speed Vc of a point on the periphery of the tool at any time point in this period of time is obtained as:

Vc=(n*π*D)/1

The following formula is obtained by conversion:

n=Vc/(π *D)

Notice! Our tool uses millimeters (mm) as the unit, so the unit of speed Vc in the previous formula is: mm/min

After the conversion of the length (1m=1000mm), we have this common formula:

After simplifying the equation, we have our formula:

Notice!

Here, the unit of D (tool diameter) is still mm (millimeter), and the unit of Vc (line speed) has become: M/min (meter/minute)